Engines

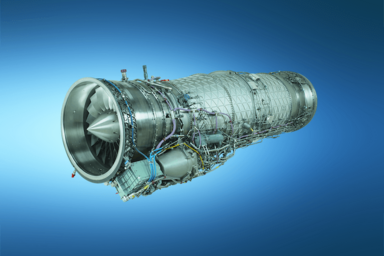

GTF™ engine family

The Pratt & Whitney GTF™ engine family is among the most eco-efficient engines on the market today. To date, the GTF engine family has saved nearly 6 billion liters of fuel and avoided 17 million metric tons of CO2 emissions. MTU’s contributions include the high-speed low-pressure turbine and the forward four stages of the high-pressure compressor.

GE9X

The GE9X will be the engine for the new Boeing 777X long-haul aircraft. MTU is responsible for the development, manufacture, assembly and repair of the turbine center frame.

Application: Boeing 777X

Thrust category: 100,000 lbf

EIS: planned

V2500

MTU develops and manufactures the IAE V2500 engine in cooperation with Pratt & Whitney, PWAEI and Japanese Aero Engines Corporation. By now, the V2500 has logged more than 280 million flight hours and is maintained at various MTU Maintenance locations.

Application: Airbus A319/320/321, Boeing MD-90, Embraer C-390 Millenium

Thrust category: 22,000 – 33,000 lbf

EIS: 1989

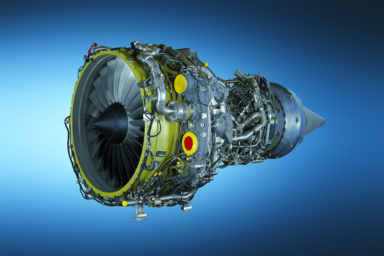

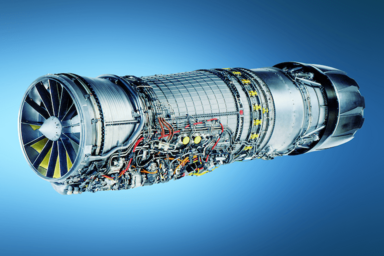

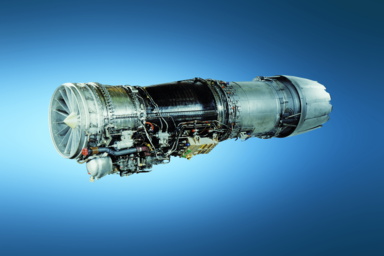

EJ200

The EJ200, which powers the Eurofighter Typhoon, is built by EUROJET Turbo GmbH, a consortium with MTU, Rolls-Royce, Avio Aero and ITP Aero as stakeholders. It was for the EJ200 that MTU first engineered compressor stages in blisk design; these are now also used in MTU components for commercial engines.

Application: Eurofighter Typhoon

Thrust category: 20,000 lbf

EIS: 2003

NGFE

As part of the Future Combat Air System (FCAS), MTU will develop, manufacture and support the New Generation Fighter Engine (NGFE) together with Safran Aircraft Engines and ITP Aero. MTU is responsible for its flagship products, the high-pressure compressor and low-pressure compressor and is the lead for all maintenance and service activities.

Application: New Generation Fighter

Planned completion of fighter: 2040s

CF6

This success story is one of the best-selling engines in its class and is used in medium-haul and long-haul aircraft. MTU manufactures parts of the CF6 turbine and compressor—and has now produced over a million of these components.

Application: e.g. Airbus A300, Boeing 747, C-5M Super Galaxy

Thrustcategory: 41,500 – 69,800 lbf

EIS: 1971 (CF6-6)

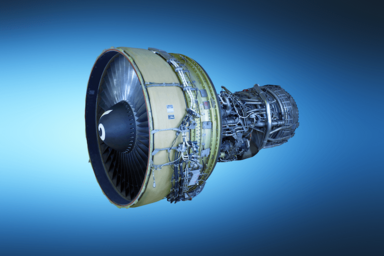

CFM56-5B/-7B

The CFM56 engine family comprises five different models, two of which are looked after by MTU Maintenance. CFMI, a 50/50 cooperation between GE and Safran Aircraft Engines, has delivered more than 30,000 engines to date.

Application: Boeing 737, Airbus A320 family

Thrust category: 18,500–34,000 lbf

EIS: 1982

GE90-110B/-115B

The GE90 Growth is one of the largest and most powerful engines in the world. MTU Maintenance Hannover is one of the first maintenance providers worldwide licensed to repair and undertake major overhaul of the GE90 Growth and provides comprehensive MRO, on-wing, on-site and AOG services.

Application: Boeing 777-200LR/-300ER/Freighter

Thrust category: 100,000 lbf

EIS: 2004

GEnx

The GEnx is designed for medium-capacity long-haul aircraft. It is based on the proven architecture of the GE90 and is set to replace the highly successful CF6. MTU is responsible for the development, manufacture, assembly and repair of the turbine center frame.

Application: e.g. Boeing 787 Dreamliner

Thrust category: 66,500–76,100 lbf

EIS: 2012

CF34-8/-10E

The CF34-family is the world’s most common and best-selling engine familiy in its class. It has logged more than 200 million flight hours since its entry into service. MTU Maintenance Berlin-Brandenburg looks after the CF34-8 and CF34-10E models.

Application: e.g. Embraer 170/190, Bombardier CRJ700/900/1000

Thrust category: 13,800–20,400 lbf

EIS: 2001

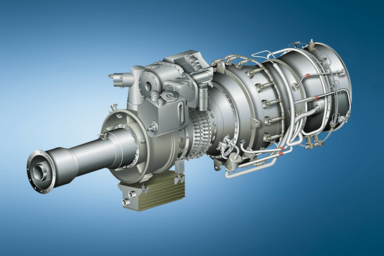

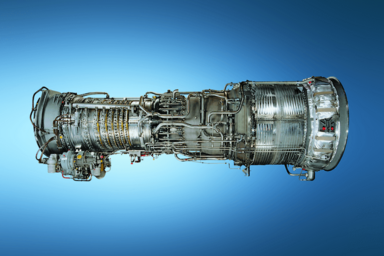

TP400- D6

The TP400-D6 is the most powerful turboprop in the West. It offers impressive robustness, efficiency and low lifecycle costs in tactical and strategic operations. MTU developed the TP400-D6 with ITP Aero, Rolls-Royce and Safran Aircraft Engines as part of the Europrop International (EPI) joint venture.

Application: Airbus A400M

Power (at sea level): 11,000 shp

EIS: 2013

LEAP-1A/-1B

CFM International’s LEAP engine family is used in the Airbus A320neo (LEAP-1A) and the Boeing 737 MAX (LEAP-1B), among others. MTU Maintenance Zhuhai is responsible for servicing these two models.

Application: Airbus A320neo, Boeing 737 MAX

Thrust category: 28,000–35,000 lbf

EIS: 2016

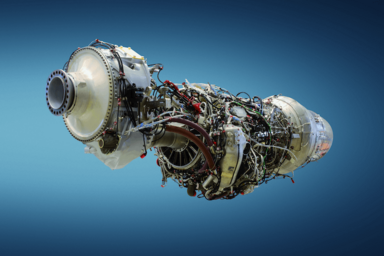

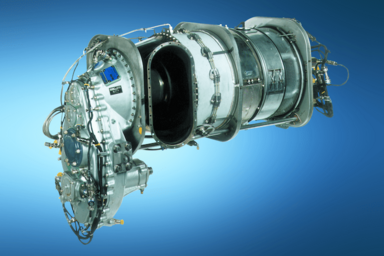

T408

The T408 is a turboshaft engine that has so far been installed in the U.S. Marine Corps’ Sikorsky CH-53K heavy-lift helicopter. MTU contributes the power turbine.

Application: Sikorsky CH-53K

Maximum power: 7,510 shp

EIS: 2019

PW800

The PW800 engine features the same proven core technology as the efficient Pratt & Whitney GTF™ engine family. MTU’s workshare in this engine encompasses the high-pressure compressor and the low-pressure turbine—its flagship products.

Application: Gulfstream G400/G500/G600, Dassault Falcon 6X

Thrust category: 10,000 – 20,000 lbf

EIS: 2018

V2500

The PW300 family offers a wide range of applications for business and regional jets. MTU has been collaborating with Pratt & Whitney Canada on this engine family since 1985. MTU’s involvement covers the PW305, PW306 and PW307 models.

Application: e.g. Dassault Falcon 7X/8X

Thrust category: 4,700 – 7,000 lbf

EIS: 1992

GP7000

The GP7000 is used in the long-haul sector and powers what is currently the world’s largest passenger aircraft, the Airbus A380. It is lead developed, produced and distributed by the Engine Alliance. MTU is involved in the development and manufacture of various components as well as in the maintenance of the low-pressure turbine.

Application: Airbus A380

Thrust category: 70,000–81,500 lbf

EIS: 2008

PW4000

The PW4000 is one of the largest and most powerful engines in the world. MTU is responsible for developing and manufacturing key parts of the seven-stage low-pressure turbine for all three versions. It is the largest low-pressure turbine ever developed by MTU.

Application: Boeing 777-200/-200ER/-300

Thrust category: 74,000 – 98,000 lbf

EIS: 1995

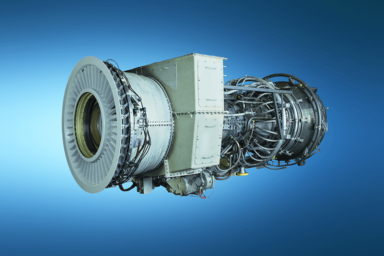

RB199

The RB199 was developed and produced to power the Panavia Tornado multirole fighter jet. This extraordinarily successful engine marked the first time that MTU had contributed independently developed and built components, such as the intermediate-pressure and high-pressure compressor and the intermediate-pressure turbine.

Application: Panavia Tornado

Thrust category: 16,000 – 17,000 lbf

EIS: 1979

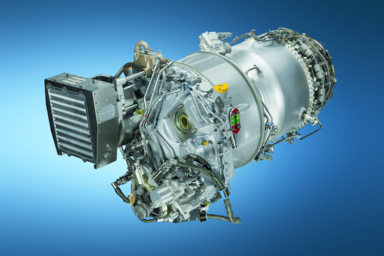

MTR390

This turboshaft engine powers the Tiger support helicopter co-developed by France and Germany. In 2011, an uprated version of the engine (the MTR390-E) was developed that delivers 14 percent more power. MTU develops and manufactures the high-pressure turbine and combustor, among other things.

Application: Airbus Helicopters Tiger

Maximum power: 1,467 shp

EIS: 2013 (MTR390-E)

T64

The T64 powers medium-weight transport helicopters. A total of 247 T64 engines were delivered. MTU manufactured its high-pressure turbine and high-pressure compressor, among other components. Today, MTU’s T64 activities focus on maintenance.

Application: Sikorsky CH-53G, GS, GA, GE

Maximum power: 4,330 shp

EIS: 1972

PW2000

The PW2000 engines are used in commercial and military applications for medium- and long-haul operations. MTU’s low-pressure turbine for the PW2000 was the first the company had developed independently for a commercial application.

Application: Boeing 757, Boeing C-17 Globemaster III

Thrust category: 37,500 – 43,000 lbf

EIS: 1984

PW6000

The PW6000 marks the first time MTU has had sole responsibility for a commercial core engine. The engine stands out by its high efficiency and its simplistic design. Designed for short-haul service, the PW6000 was used in the Airbus A318.

Application: Airbus A318

Thrust category: 18.000 – 24.000 lbf

EIS: 2007

PW500

The PW500 engines are two-shaft turbofans. MTU is contributing the development and manufacture of the entire low-pressure turbine, including the exit case and mixer, for the PW530 and PW545 models.

Application: e.g. Cessna Citation Bravo/Excel/XLS

Thrust category: 3,000 – 4,500 lbf

EIS: 1997

JT8D-200

The JT8D family is one of the world’s best-selling jet engine families and has already logged more than 675 million flight hours since entering service. MTU is involved in the -200 series and is responsible for manufacturing individual parts of various assemblies.

Application: Boeing MD-80

Thrust category: 18,500–21,700 lbf

EIS: 1980

PT6A

The PT6 is an exceptionally light-weight turboshaft engine. It is used among others on business aircraft. Special versions of the engine also power transportation and military aircraft. Maintenance is carried out via the Pratt & Whitney Canada Customer Service Centre.

Application: e.g. Cessna Caravan; Beechcraft King Air

Maximum Power: 1,900 shp

EIS: 1973

PW100/150A

The PW100 turboprop family powers regional aircraft in the 30- to 90-seat category and with a range of up to 750 miles. These engine models are characterized by their high reliability and efficiency and their long service life. Maintenance is carried out via the Pratt & Whitney Canada Customer Service Centre.

Application: e.g. Bombardier Q400; ATR72

Maximum power: 5.000 shp

EIS:1984

PW200

Pratt & Whitney Canada’s PW200 is an engine for light and medium helicopters. It is characterized amongst other things by its simple and robust design featuring a centrifugal compressor, a reverse-flow combustor and a single-stage turbine. Maintenance is carried out at MTU Maintenance Berlin-Brandenburg.

Application: e.g. Airbus Helicopters H135; Bell 427

Maximum power: 700 shp

EIS: 1998

PW210

The PW210 fleet has more than 360,000 flying hours and is the benchmark for a new generation of twin-engine helicopters for medium-class helicopters. Maintenance is carried out via the Pratt & Whitney Canada Customer Service Centre.

Applications: Leonardo Helicopters AW169; Sikorsky S-76D

Maximum Power: 1,000 shp

EIS: 2014

PT6B/-C/-T

The turboshaft engines of the PT6 family, the PT6B, -C, and -T, are used in single- or twin-engine helicopters. These extremely successful engine models are appreciated for their reliability and robustness. Maintenance is carried out via the Pratt & Whitney Canada Customer Service Centre.

Application: e.g. Airbus Helicopters H175; Agusta Westland 119/139

Maximum power: 2,000 shp

EIS: 1986

PW600

The PW600 is designed for the new, very light business jets. The compact and lightweight turbofan family uses half the parts of a conventional turbofan engine. Maintenance is carried out via the Pratt & Whitney Canada Customer Service Centre.

Application: e.g. Cessna Mustang, Eclipse 500

Thrust category: 950 – 1,750 lbf

EIS: 2007

F110

The F110-GE-129 powers the Boeing F-15 and Lockheed Martin F-16 fighter aircraft and has established itself as one of the most successful engines for combat aircraft in the history of the U.S. Air Force. MTU manufactures turbine disks for the low-pressure compressor for the F110-GE-129.

Application: Lockheed Martin F-16; Boeing F-15 / F-15 EX

Thrust category: 29,000 lbf

EIS: 1986

F414

The F414 powers Boeing’s F/A-18 Super Hornet twin-engine fighter and the E/A-18G Growler electronic warfare version, among others. MTU produces various parts of the F414’s high- and low-pressure turbine.

Application: e.g. F/A-18 Super Hornet, EA-18G Growler

Thrust category: 22,000 lbf

EIS: 1995

Larzac 04

The Larzac 04 powers the Alpha Jet trainer and light ground-attack aircraft. MTU took over the production of about 25 percent of the parts and the development engineering support. MTU’s manufacturing and support share primarily covers the hot section of the engine—from the combustor inlet to the turbine exit.

Application: Dornier-Dassault Alpha Jet

Thrust category: 3,000 lbf

EIS: 1979

LM6000™

The LM6000™ industrial gas turbine is derived from GE’s CF6-80 aircraft engine and is mainly used in power generation. MTU Maintenance has provided MRO services for this type of gas turbine since 1996.

Application: power generation, mechanical drive systems

Power category: 44,7 – 58 MW

Commercial aircraft engine: CF6-80

LM2500™

The LM2500™ is an industrial gas turbine made by GE and is based on the CF6-6 commercial aircraft engine. It is the most widely used gas turbine in the 25 – 37 MW power category, and MTU has been maintaining it since 1981.

Application: e.g. power generation, marine propulsion systems

Power category: 25 – 37 MW

Commercial aircraft engine: CF6-6